Annealing and Pickling Lines

for silicon steels

An annealing and pickling line (APL) softens the hot rolled strip by heating the silicon steel up to the annealing temperature, then removes the superficial scale thanks to a pickling section. The main goal of this line is to deliver a product that can be cold rolled. It is used for the production of grain oriented (GO) and non grain oriented (NGO) steels.

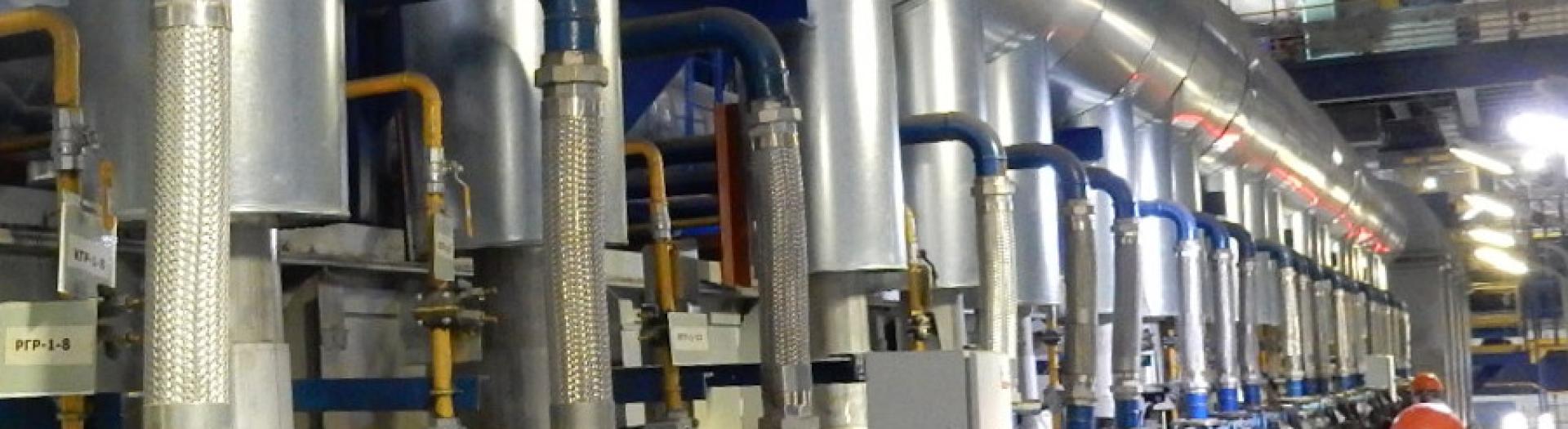

Drever International furnaces allow to heat the strip in a controlled atmosphere to avoid further oxidation of the surface before the pickling process. They also have a perfect control of the heating and of the cooling rate requested to perform the heat treatment of the most advanced steel grades.

APL for silicon steels

The silicon steel strip coming from the hot rolling is too brittle to be further processed by cold rolling. To soften its microstructure, it must be reheated to a temperature in the range of 1000°C – 1150°C: this is the annealing. For GO production, the strip is then slowly cooled down, soaked and quickly cooled down thanks to a water cooling section. For NGO production, after annealing, the strip is soaked and then eventually slowly cooled down. The final cooling is achieved in a water cooling section. In order to limit the oxidation of the strip, the atmosphere of the heating, soaking and slow cooling is neutral or reducing.

Our mathematical model as well as our dedicated control system drive the temperature of the different zones of the furnace to reach the requested microstructure and properties at the end of the line.

Configuration

The usual configuration for the Annealing and Pickling Line s is horizontal.

Heating

Drever International supplies a combination of two technologies to reach the desired annealing temperature:

- The direct flame furnace (DFF)

- Electrical heating elements

Cooling

After the annealing and the soaking, Drever International relies on a combination of three technologies to cool down the strip:

- Cooling tube section that can be equipped with electrical heating

- Air cooling section

- Water cooling section

Drever International delivers

- The annealing furnace and the cooling section

- The control system and a mathematical model of the furnace

Our parent company, SMS group and its affiliates deliver all the other equipment of the line.

More information on SMS group offer