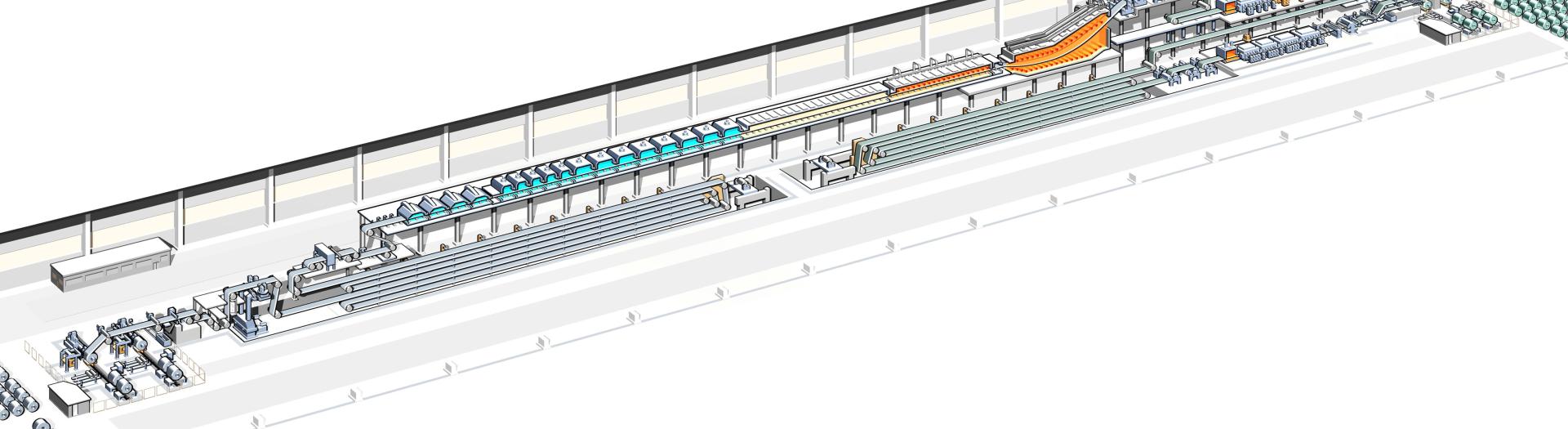

Flattening and coating lines for silicon steels

A flattening and coating line (FCL) is used to apply and dry the insulation varnish on the strip, then to reheat the strip, release the internal tensions and perform a hot stretching.

The main purpose of this line is to deliver a final product that can be used to manufacture transformers.

Drever International furnaces allow to heat the strip in a controlled atmosphere to keep a clean surface after the coating process. They also have a perfect control of the heating and of the cooling rate requested to perform the heat treatment of the most advanced steel grades.

After the high temperature annealing, the strip is delivered to the flattening and coating line. The steel strip is firstly coated with insulating varnish and the drying takes place in a catenary furnace. Then the strip is reheated in a radiant tube furnace to a temperature in the range of 850°C – 900°C in order to release internal tensions. Then the strip is cooled down slowly and then quickly. The radiant tube furnace, the soaking and the slow cooling sections are filled by a non-oxidizing HNx atmosphere, a mixture of hydrogen and nitrogen. An air cooling section cools the strip so it can be used in downstream processes.

Our mathematical model as well as our dedicated control system drive the temperature of the different zones of the furnace to reach the requested microstructure and properties at the end of the line.

Configuration

The usual configuration of flattening and coating line is horizontal. It includes a:

- Catenary furnace

- Continuous annealing furnace and cooling section

Heating

Drever International supplies a combination of three technologies to reach the desired annealing temperature:

- Direct flame in the catenary furnace (DFF)

- Radiant tube furnace (RTF)

- Electrical heating elements

Cooling

After the annealing and the soaking, the strip must be cooled down to the exit temperature. A slow cooling is followed by a quicker cooling provided by HNx jets.

- Cooling tube section

- Fast cooling with plenums blowing cold HNx

- Air cooling

Drever International delivers

- The annealing furnace and the cooling section

- The control system and a mathematical model of the furnace

Our parent company, SMS group and its affiliates deliver all the other equipment of the line.

More information on SMS group offer